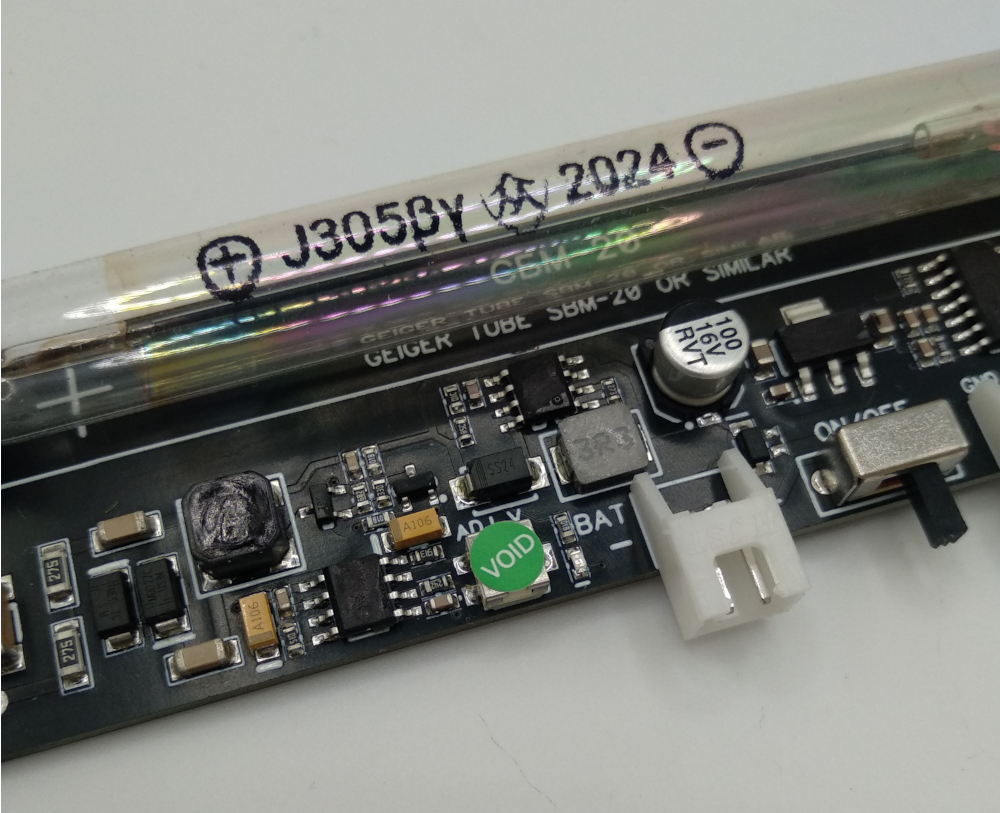

As new users of the GGreg20_V3 module may have noticed, the board now comes in black. The black PCB is likely the tenth generation of the GGreg20_V3 module. This version features an improved circuit for smoother high-voltage regulation and a voltage limit of approximately 600 volts.

The module also comes with two stickers. The first is a Q.C. (Quality Control) sticker on the back of the board. The second is a VOID (warranty) sticker placed on the module’s high-voltage adjustment potentiometer.

Since implementing these changes—over six months ago—we’ve had the opportunity to gather feedback from our customers. One of the most common questions directed at our support team has been about the VOID sticker. Naturally, people are curious (and sometimes even genuinely frustrated) about why we’ve restricted high-voltage adjustments and what this sticker actually means in practice.

Let’s go over everything step by step.

Over the past year (2023–2024), we grew increasingly concerned about the statistics on sudden module failures. Diagnostics consistently pointed to excessively high voltage as the likely cause. Over time, this inevitably damages module components and can even lead to the failure of the Geiger tube.

That’s why, starting around September–October 2024, we introduced several improvements to our internal quality control procedures. The Q.C. sticker is now applied at the final stage of product testing.

Additionally, we decided to further restrict access to the potentiometer’s settings.

Since the module requires precise tuning and this part of the circuit is analog, the potentiometer’s setting can be easily disrupted—whether during use, due to vibrations in transport, or for other reasons. We hope that the VOID sticker now serves as an additional safeguard, keeping the potentiometer fixed in the position set by our specialists.

This sticker also acts as a warning for both beginners and experienced users: if you’re not sure, don’t touch it.

Our goal is to ensure that anyone considering adjusting the potentiometer first makes sure they know what they’re doing, understands the correct procedure, and has the necessary tools.

Now, what about cases where adjusting the high voltage is actually necessary? As far as we know, there is only one such scenario: when replacing the Geiger tube with one that requires significantly different operating voltage.

For example, if you’re swapping a J305 tube for an SBM20 (or vice versa), there’s no need to adjust the module, since their recommended operating voltages are almost the same—380V for J305 and 400V for SBM20. However, if you’re replacing a J305 with an LND712, then an adjustment is necessary to change the operating voltage from 400V to 500V.

Some customers have asked: What should I do if I absolutely need to adjust the potentiometer to a different voltage?

Warning!

The module operates at voltages that can be hazardous to health and life. Do not violate safety regulations or electrical installation standards. If you’re unsure, it’s best to consult a qualified specialist with the proper experience and certifications.

Our Recommendations

- Review the technical note on initial self-diagnosis of voltages on the GGreg20_V3 module.

- Use the knowledge gained (see point 1) to correctly measure the voltages on the module without adjusting the potentiometer. Ensure that you are using the appropriate measuring tools and following the procedures outlined in the note.

- Contact (via email) our support team to inform us that you plan to adjust the settings. If needed, consult with our specialists for guidance.

- Adjust the potentiometer to the required voltage by removing the VOID sticker.

Conclusions:

- Since implementing Q.C. and VOID stickers as part of our improved procedures, we have not received a single report of GGreg20_V3 module failure.

- If you need to replace an SBM20 tube with a J305, there is no need to adjust the potentiometer. The operating voltage ranges of these Geiger tubes overlap, so you can simply swap the tube.

- Every module shipped with a Q.C. sticker has been properly calibrated and extensively tested. Our test bench records measurement statistics to verify the performance and stability of both the module and the tube over an extended testing period—typically about an hour. Only after passing these tests does our specialist approve the module for shipment.

- The extended final testing phase also allows for selective thermal control of module components, ensuring long-term reliability.

- The VOID warranty sticker on the potentiometer does not restrict you as a user. It simply serves as a warning that adjusting the potentiometer without proper knowledge and tools is dangerous. By breaking the VOID seal, the user knowingly accepts the associated risks.

- If you follow the documentation and handle the module correctly, you won’t need warranty service, repairs, or replacement for your GGreg20_V3.

- Simply leave the VOID sticker intact and avoid adjusting the settings unless absolutely necessary.